Elevate your milling capabilities with the VEVOR Rotary Table for Milling Machines. This 4-inch rotary table is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces. With its 3-jaw chuck and serrated jaw, it ensures a firm grip on even the smallest workpieces, providing secure machining of small components. The handwheel operation and crystal-clear scales allow for precise measurements, while the horizontal and vertical installation options make it compatible with various milling machines. Crafted from HT250 cast iron, this rotary table offers exceptional durability and longevity. Take your milling game to the next level with the VEVOR Rotary Table.

Why Consider This Product?

Elevate your milling capabilities with the VEVOR Rotary Table for Milling Machines. Designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces, this rotary table is ideal for small milling machines. Its versatility makes it suitable for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery industries, this rotary table plays an essential role in mechanical processing.

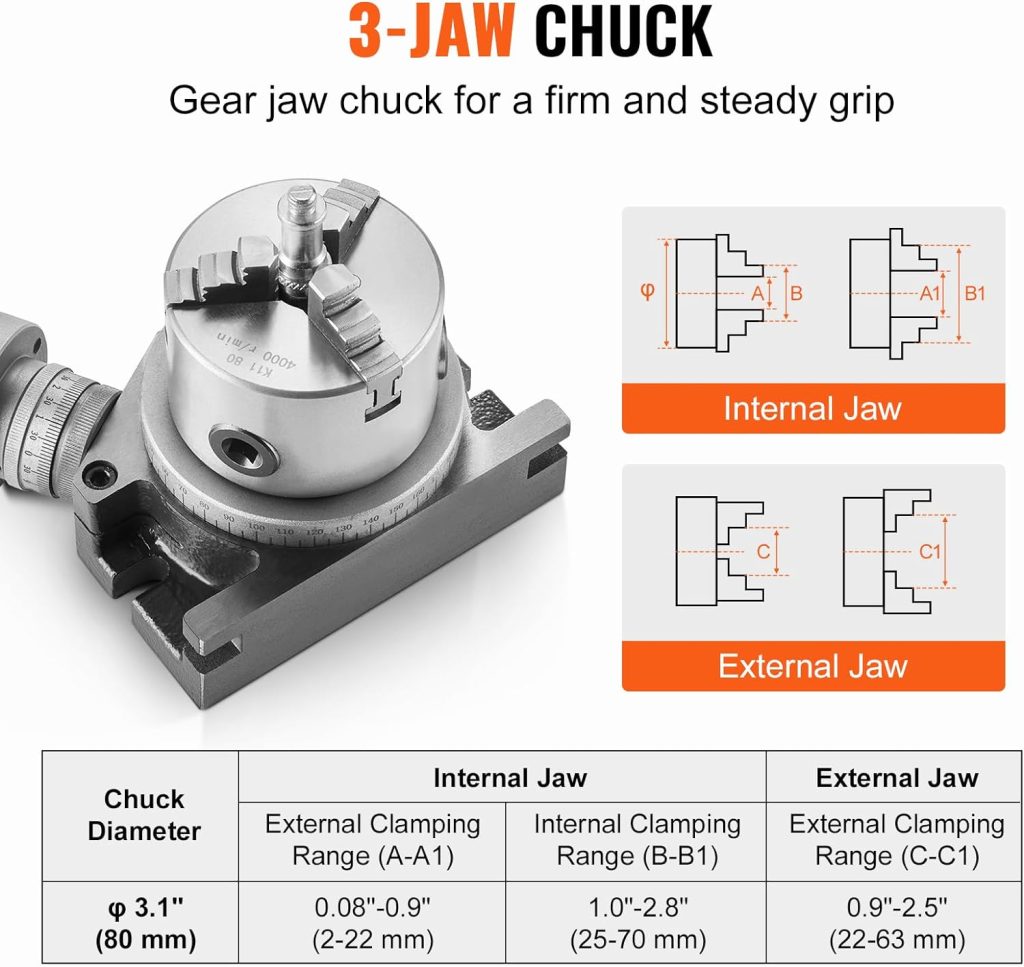

Featuring a 4-inch diameter and a 3-jaw chuck, the VEVOR Rotary Table ensures a firm grip on even the smallest workpieces, thanks to its serrated jaw. The chuck diameter measures 3.1 inches, providing ample space for secure clamping. Its internal jaw can be used for both internal and external clamping, with an external clamping range of 0.08 to 0.9 inches and an internal clamping range of 1.0 to 2.8 inches. The addition of an external jaw expands the clamping range to 0.9 to 2.5 inches.

Features and Benefits

Precise Measurements and Control

The VEVOR Rotary Table is operated by a handwheel, allowing for precise control over the rotation. The scale on the handwheel provides clear measurements, with a scale number of 100. The table itself is marked with 360 degrees, ensuring accurate positioning and rotation. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, providing intuitive operation and precise control over even the slightest rotation.

Flexible Installation Options

This rotary table can be mounted either horizontally or vertically, depending on your milling machine’s requirements. When mounted horizontally, the chuck top height is 4.7 inches, with a tolerance of ±3 mm. If mounted vertically, the chuck center height is 2.0 inches. The VEVOR Rotary Table is compatible with both industrial and home-use milling machines, as long as the milling machine’s tool height is higher than the vertical or horizontal installation heights. The table’s bottom features positioning slots, ensuring easy and secure attachment to your milling machine.

Exceptional Durability and Longevity

Crafted from HT250 cast iron, the VEVOR Rotary Table offers exceptional durability and wear resistance. The high-hardness surface resists scratches and corrosion, ensuring a long lifespan even under heavy loads, high pressure, and rapid rotation. This rotary table is built to last, allowing you to step up your milling game and achieve high-quality performance in your operations.

Product Quality

The VEVOR Rotary Table is designed and manufactured with precision, ensuring high-quality performance in milling operations. The use of HT250 cast iron provides excellent durability and wear resistance. Its scratch-resistant and corrosion-resistant surface ensures a long lifespan, even under challenging conditions. With its precise measurements and intuitive operation, this rotary table offers exceptional quality for achieving accurate and precise machining results.

What It’s Used For

The VEVOR Rotary Table is a versatile tool that finds applications in various industries. Its precise positioning, rotation, indexing, and clamping capabilities make it suitable for a wide range of machining tasks. Here are some common uses for this rotary table:

Curved Surface Machining

The VEVOR Rotary Table enables precise machining of curved surfaces. Its ability to position and rotate workpieces with precision ensures accurate and smooth machining results. Whether you are working on automotive parts, mold-making, or general machinery components, this rotary table provides the necessary functionality for curved surface machining.

Elongated Hole Processing

When it comes to elongated hole processing, the VEVOR Rotary Table excels. Its precise positioning and indexing allow for accurate drilling and processing of elongated holes. This feature is particularly useful in industries that require precise hole patterns or design elements.

Precision Drilling

For precision drilling tasks, the VEVOR Rotary Table is a valuable tool. Its ability to position workpieces accurately and its fine control over rotation ensure precise drilling results. Whether you are working on small components or larger parts, this rotary table provides the necessary stability and accuracy for achieving precise drill holes.

General Mechanical Processing

The VEVOR Rotary Table finds widespread use in general mechanical processing tasks. Its versatility and precision make it suitable for a wide range of applications, allowing users to perform various machining operations with ease. From milling to drilling, this rotary table enhances the capabilities of small milling machines, making it an invaluable tool for mechanical processing tasks.

Product Specifications

| Specification | Dimension |

|---|---|

| Milling Machine | φ4” / 100 mm |

| Chuck Diameter | φ3.1” / 80 mm |

| External Clamping Range | 0.08”-0.9” / 2-22 mm |

| Internal Clamping Range | 1.0”-2.8” / 25-70 mm |

| External Clamping Range with External Jaw | 0.9”-2.5” / 22-63 mm |

| Horizontal Installation Chuck Top Height | 4.7” / 120 mm (±3 mm) |

| Vertical Installation Chuck Center Height | 2.0” / 50 mm |

Who Needs This

The VEVOR Rotary Table is a must-have tool for individuals and businesses involved in milling and machining operations. Whether you are a professional in the automotive, mold-making, or general machinery industry, or a hobbyist looking to enhance your capabilities, this rotary table is designed to meet your needs. With its precise positioning, rotation, indexing, and clamping capabilities, the VEVOR Rotary Table is a valuable addition to any milling operation.

Pros and Cons

Pros

- Precise positioning, rotation, indexing, and clamping capabilities.

- Suitable for curved surface machining, elongated hole processing, and precision drilling.

- Versatile and widely used in automotive, mold-making, and general machinery industries.

- High-quality construction from HT250 cast iron for durability and wear resistance.

- Clear scales and intuitive operation for precise measurements and control.

- Compatible with both horizontal and vertical installation.

Cons

- May not be suitable for larger milling machines.

- Requires a milling machine with compatible tool height for installation.

FAQ’s

-

Is the VEVOR Rotary Table compatible with my milling machine? Yes, as long as your milling machine’s tool height is higher than the vertical or horizontal installation heights of the rotary table, it is compatible. Additionally, the table’s bottom features positioning slots for easy and secure attachment.

-

Can I use the VEVOR Rotary Table for curved surface machining? Yes, the rotary table is designed for precise positioning, rotation, indexing, and clamping, making it suitable for curved surface machining tasks.

-

How precise are the measurements on the VEVOR Rotary Table? The rotary table features clear scales on both the handwheel and the table itself for precise measurements. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, allowing for precise control over rotation.

What Customers Are Saying

Customers are highly satisfied with the VEVOR Rotary Table for Milling Machines. They praise its precise positioning and rotation capabilities, which enable accurate and smooth machining. The durability and wear resistance of the HT250 cast iron construction receive positive feedback, ensuring customers of its long lifespan even under heavy loads. The clear scales and intuitive operation also receive commendation, making it easy for customers to achieve precise measurements and control.

Overall Value

The VEVOR Rotary Table for Milling Machines offers exceptional value for users in need of precise positioning, rotation, indexing, and clamping capabilities. Its versatility makes it suitable for various machining tasks, including curved surface machining, elongated hole processing, and precision drilling. With its high-quality construction and durability, this rotary table ensures a long lifespan even under demanding conditions. The clear scales and intuitive operation enhance the overall value, allowing users to achieve precise measurements and control.

Tips and Tricks For Best Results

To achieve the best results with the VEVOR Rotary Table, consider the following tips:

- Ensure that your milling machine’s tool height is higher than the vertical or horizontal installation heights of the rotary table.

- Take advantage of the clear scales on the handwheel and the table itself for precise measurements.

- Familiarize yourself with the worm gear ratio of 1:36 to understand the relationship between the handwheel rotation and the table rotation.

- Follow proper maintenance procedures to ensure the longevity of the rotary table.

- Always use appropriate safety precautions when operating the rotary table and working with milling machines.

Final Thoughts

The VEVOR Rotary Table for Milling Machines is a reliable and versatile tool that enhances the capabilities of small milling machines. With its precise positioning, rotation, indexing, and clamping capabilities, this rotary table enables users to achieve accurate and smooth machining results. Crafted from HT250 cast iron, it offers exceptional durability and wear resistance, ensuring a long lifespan even under heavy loads. The clear scales and intuitive operation make it easy for users to achieve precise measurements and control. Overall, the VEVOR Rotary Table provides excellent value for individuals and businesses involved in milling and machining operations.